Troubleshooting How to Safely Remove a Broken Spark Plug from Your Cylinder Head

For some of you overenthusiastic motorcycle tinkerers, you may have experienced the deep sinking feeling in your gut, when you’ve unintentionally over-tightened a spark plug in the engine block.

For some of you unlucky enough to have to deal with this issue, I have an easy, simple solution that works. There is a lot of advice online, and not all was helpful for me; however, after a lot of trial and error I found the best solution for safely removing a broken spark plug stuck in a cylinder head.

What you’ll need:

- Magnet

- WD40

- Square fluted screw extractors (set)

- Adjustable spanner/pliers

Steps for removal

Step 1.

First of all its important to remove any metal shards that may have entered the engine block or the surrounding area near the spark plug thread. You can do this by using a telesopic reach magent or alternatively you can use compressed air to blow the area clean, After the area is clean, utilise a penetrating oil such as WD-40, just to help provide some lubrication between the thread and spark plug. Don’t worry if this goes into the engine block; it will eventually evaporate when the engine is running again.

Step 2.

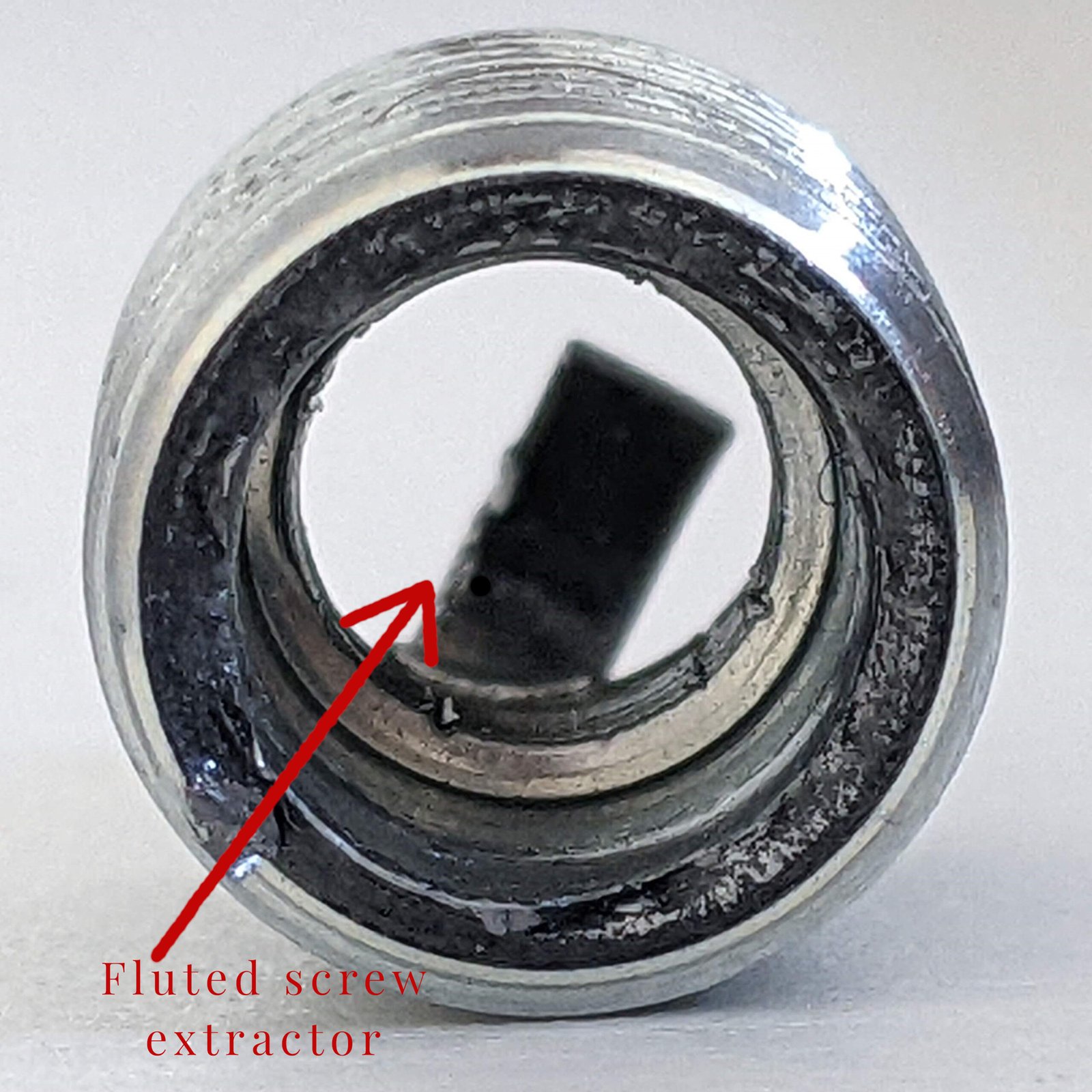

This step is the most important part. You need to get your hands on a set of square fluted screw extractors. It’s important you do not use the round spiral form, this can make the problem worse by expanding the spark plug thread into the engine block thread. A set like this will be perfect (see below image). Find the correct size that will fit into the inside of the spark plug but not too thin that it pokes through too much on the other side (in the engine block).

Additional Tip: I worked out the perfect size flute by purposefully cutting open the same type of spark plug. I then tried different-sized flute extractors to see which one would be the right fit. I highly recommend doing this extra step! Find one that will fit snug, one that will dig into the edges of the inside of the plug to gain a good grip. You also don’t want the extractor to be so small that it pokes out the other side and into the engine block.

For additional precuation, it’s worth making sure that the piston head is out of the way at bottom dead centre if possible; this will avoid the extractor hitting the piston if it happens to poke through deeper when you’re hammering in the the extractor in the next step.

Step 3

Once you’ve located the correct size square fluted screw extractor. It will need to be gently hammered in slightly so that the edge of the flute can gain a good grip on the inside of the plug. If you performed the step above by trialling it out on an old spark plug, you should have the perfect fit.

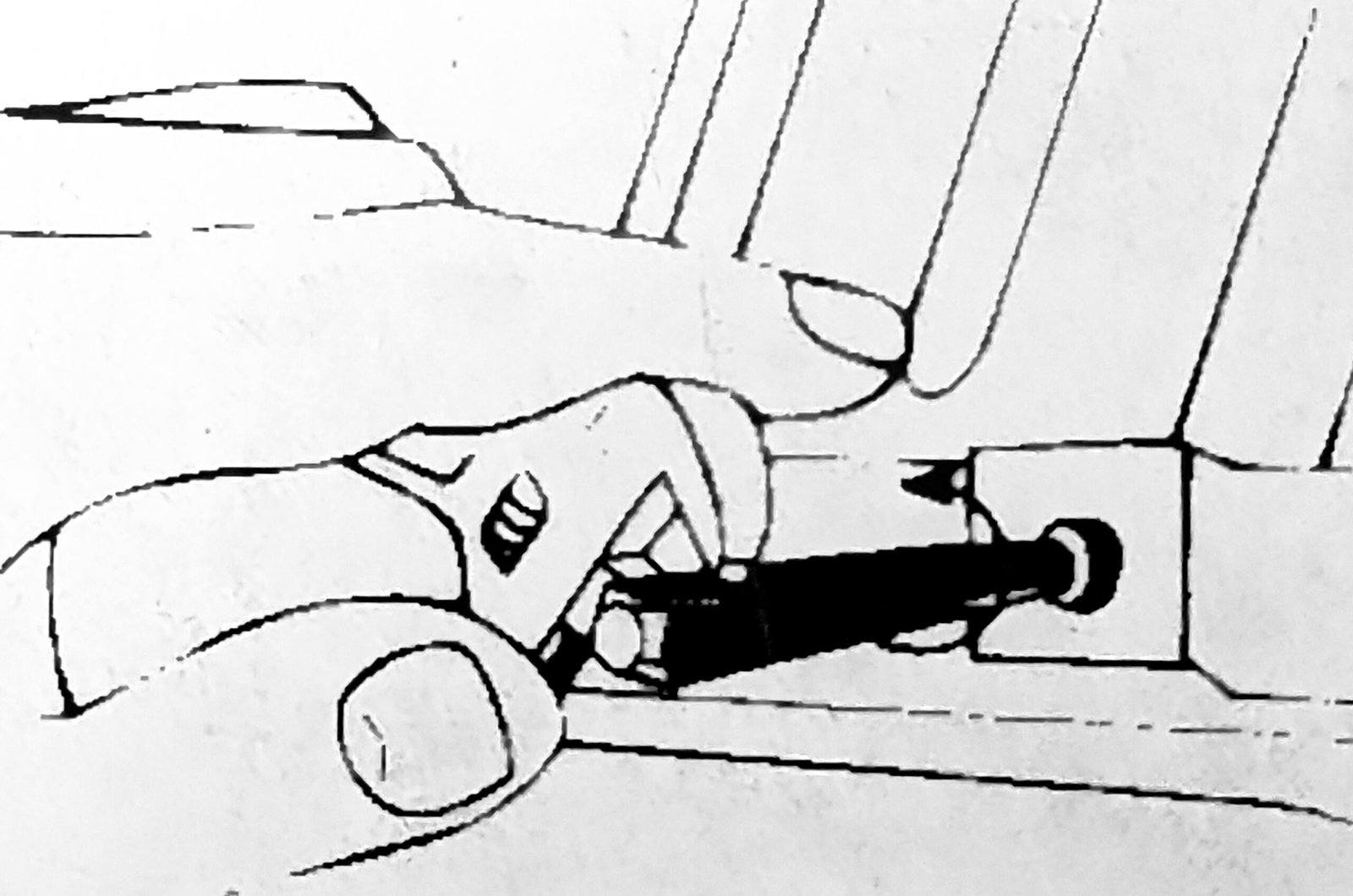

Step 4

Once it has a good grip on the inside of the plug thread, get your adjustable spanner or pliers and grip the square fluted extractor at the end sticking out. Slowly turn anticlockwise. If performed correctly, it should have more than enough grip to slowly screw out.

Step 5

Once removed, make sure to double check for any metal shards. It’s always worth running over the area again with a magnet and/or compressed air to ensure a clean cylinder.