Home » Blog articles » Maintenance »

Maintenance Balancing Your Carburettors

To ensure ultimate performance, it’s vital that multi-cylinder, carburettor fed engines get an even distribution of air/fuel mixture. Carburettor balancing involves only a few simple tools and is a skill that any enthusiast can easily master for regular engine maintenance. Here are the tools you’ll need:

- Manual or digital Vacuum gauges (I recommend manual gauges)

- Adjustable mini clamps (one per cylinder) – not required for digital gauges

- Spring hose clamp/fasteners (often included when purchasing gauges)

- Standard Philips head screwdriver (required for balancing screw)

Step 1

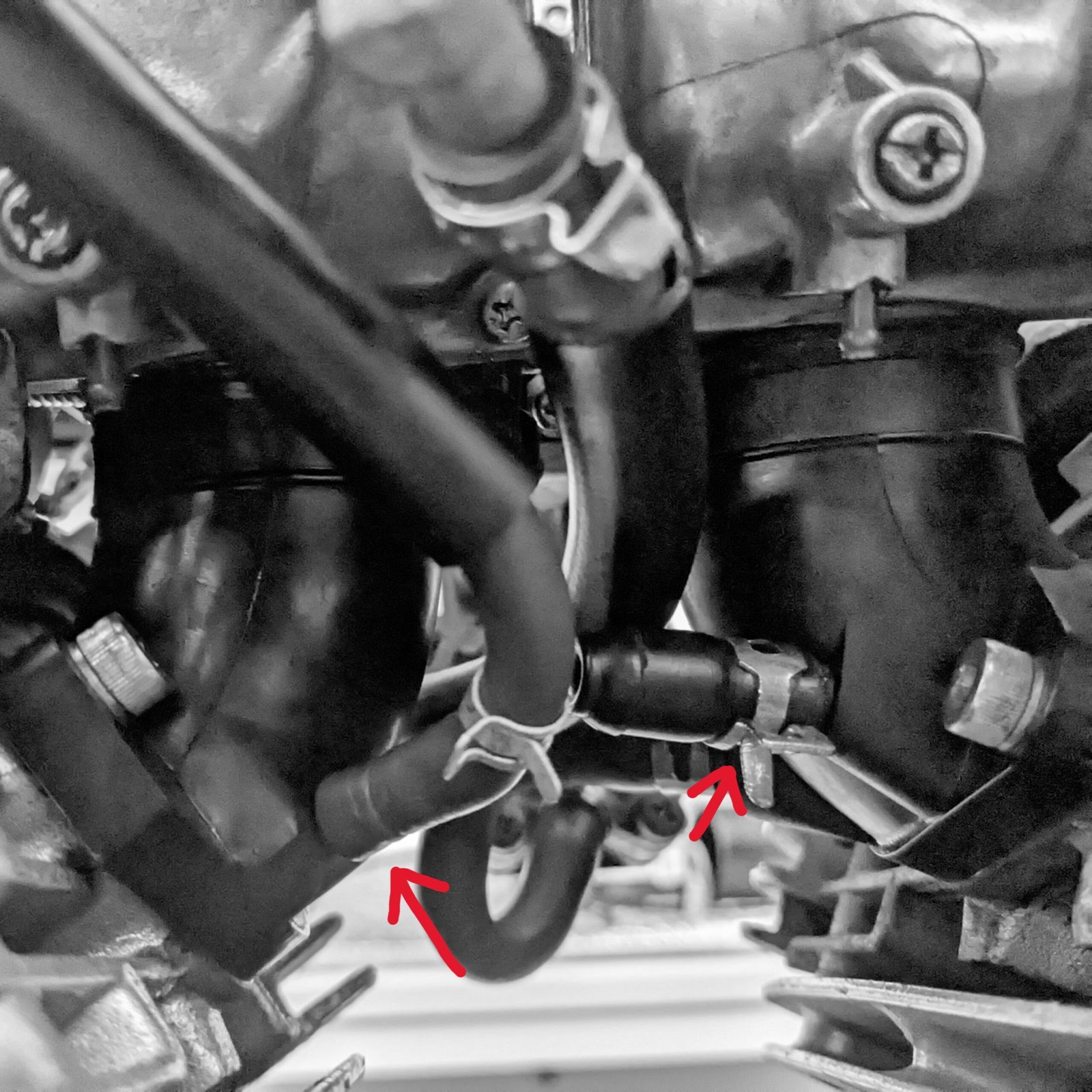

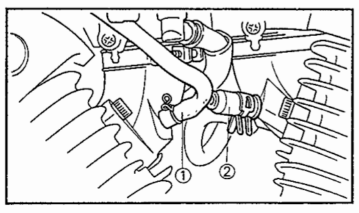

- Place your motorcycle on its centre stand. In your service manual, locate the relevant ports on the intake manifold to connect the vacuum hoses to. You will need to connect a gauge to each cylinder. For example, you will need two gauges for a twin cylinder and three for a three cylinder.

Step 2

- Connect the vacuum hoses along with the spring hose clamp to make the connections airtight. The other end of each hose that’s connected to the gauge should also have a clip. Purchasing a set of vacuum gauges should have the spring house clips included.

Step 3

- Once connected, most motorcycles will need to have their pet fuel-tap set to ‘prime’ before balancing the carbs.

Step 4

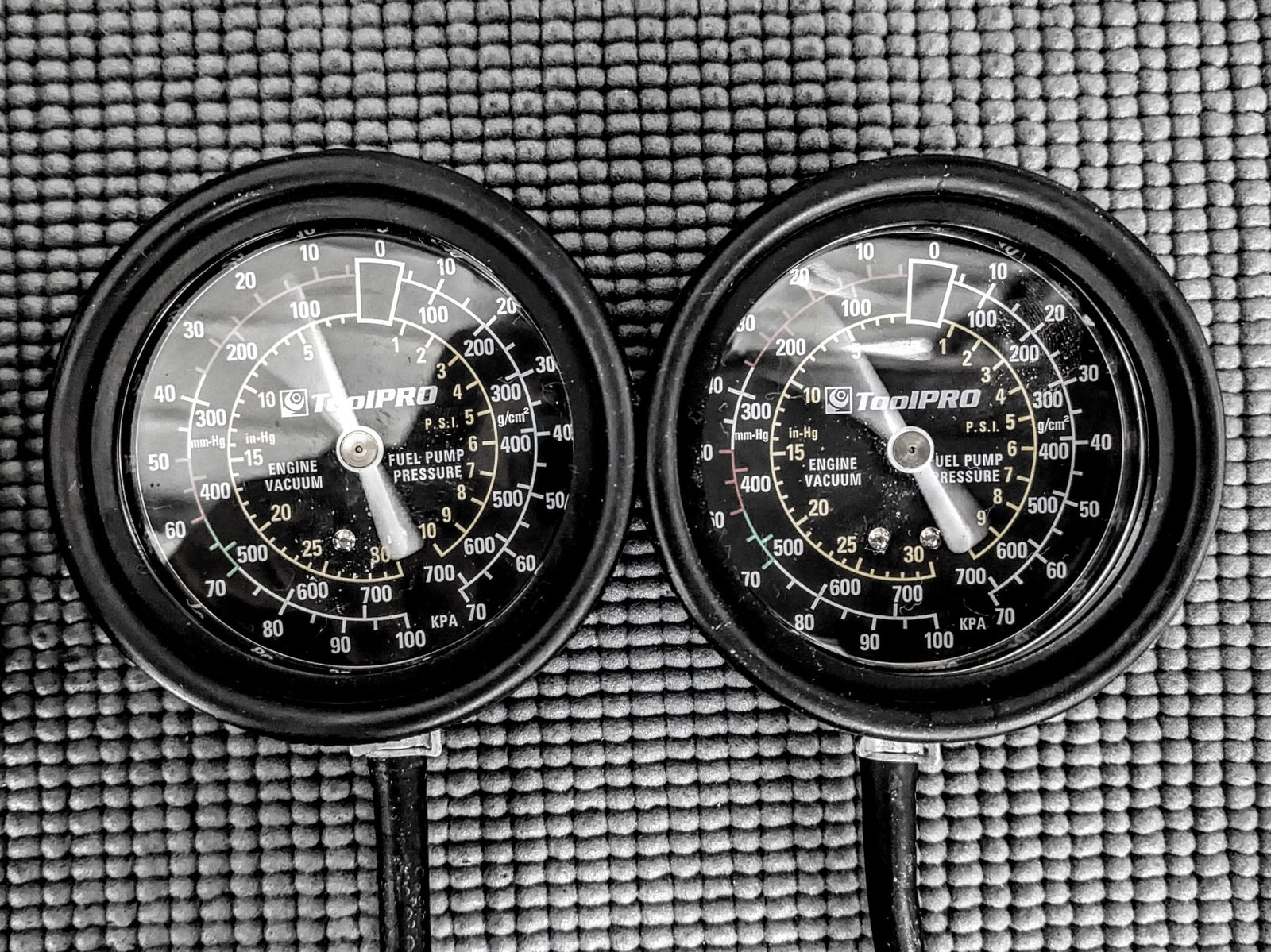

- Start the engine and race it a few times to gain a steady idle. The first thing you’ll notice will be the gauge needles flying all over the place. It is impossible to balance the carbs like this and therefore you will need to dampen the vacuum pulse to gain an accurate reading.

- If you have a manual set of vacuum gauges you will need to pinch the hose end with a clamp or adjustable pliers after starting the engine. Dampening of the vacuum pulse is required so it can be clearly read.

- On manual gauges this can be achieved by gradually restricting the vacuum hose with a clamp until there is only a very slight back and forth needle movement (if the needle stops moving you’ve cut off the pulse too much). Dampening on digital gauges is done electronically, and therefore you would not need to manually dampen the pulse for a digital set.

Step 5

- Locate the balancing or synchronising screw and get your screwdriver in place. As you begin to rotate the needle clockwise or anticlockwise, watch the gauges needle values. Assuming you have a two-cylinder, aim to balance both gauge values so that they are adjusted to their set specification within 10mm Hg or less of each other. The more even they are, the more equal the balance.

Step 6

- Once the carbs are balanced, race the engine a few times and recheck the values. If the values require a touch up, re-adjust the synchronisation screw until they’re back in balance.